Understanding the Standards of Best Industrial Waste Compactors in Manufacturing

As the manufacturing industry continues to evolve, so does the necessity for efficient waste management solutions, particularly in the context of Industrial Waste Compactors. According to a recent report by the Environmental Protection Agency, manufacturing facilities generate approximately 7.6 billion tons of industrial waste annually, underscoring the pressing need for effective disposal methods. By 2025, it is projected that advancements in technology will play a pivotal role in optimizing waste management processes, reducing environmental impact, and enhancing operational efficiency. The integration of smart technology in Industrial Waste Compactors will not only facilitate real-time monitoring and data analysis but also streamline operations, thereby minimizing costs and improving sustainability. This blog will explore the best practices and emerging trends in Industrial Waste Compactors, guiding manufacturers on how to implement these innovations for a more sustainable future.

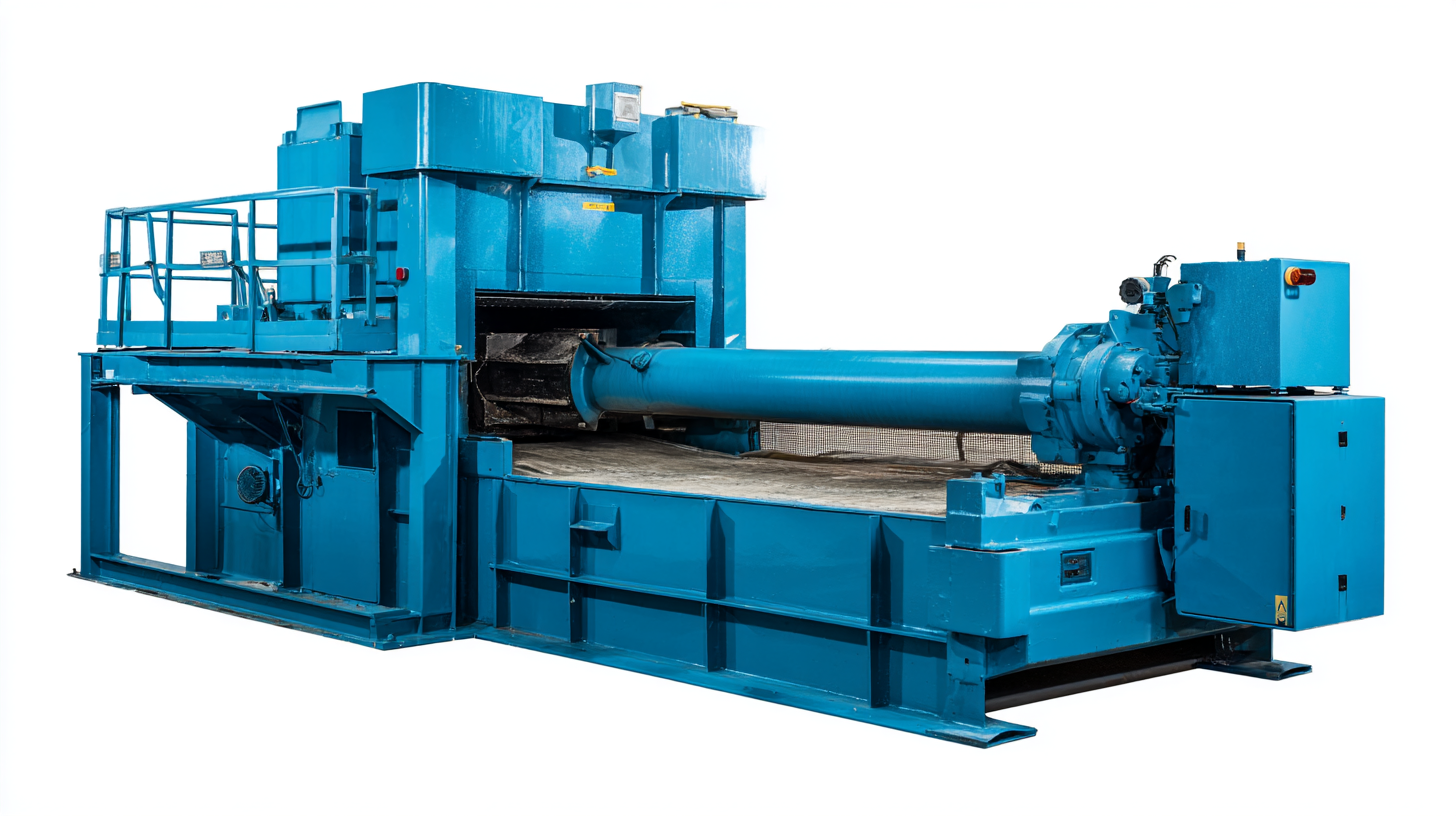

Key Features to Look for in Industrial Waste Compactors

When looking for the best industrial waste compactors for your manufacturing facility, certain key features can make a significant difference in efficiency and effectiveness. First and foremost, consider the compactor's crushing power and capacity. A model with a high compaction force will reduce the volume of waste significantly, which is not only space-saving but also cost-effective in terms of waste disposal. Additionally, ensure that the compactor has a suitable chamber size for the types of materials you typically handle, whether they are cardboard, plastics, or metal.

Another vital feature to look for is user-friendliness. Many modern compactors come equipped with intuitive control panels and automatic systems that simplify operation. This ensures that your staff can use the equipment safely and efficiently, minimizing the risk of accidents and downtime. Moreover, energy efficiency should not be overlooked; energy-efficient models can lead to substantial savings on utility bills over time.

**Tip:** Regular maintenance is essential to keep your compactor in optimal working condition. Schedule monthly check-ups to address any potential issues before they escalate.

**Tip:** Evaluate the compactor's safety features, such as emergency stop buttons and safety guards, to protect your employees while they operate the machine.

By focusing on these key features, you can select an industrial waste compactor that meets your needs while promoting safety and efficiency in your manufacturing processes.

The Role of Waste Compactors in Enhancing Manufacturing Efficiency

In the manufacturing industry, waste management is a critical aspect that directly influences operational efficiency. Waste compactors play a pivotal role in streamlining this process, significantly enhancing productivity. According to a report by Waste Management, manufacturers can reduce their waste volume by up to 90% through effective compaction, allowing for fewer collections and lower transportation costs. This reduction not only saves money but also minimizes the environmental footprint associated with waste disposal.

Additionally, implementing waste compactors can lead to improved workplace safety. The Occupational Safety and Health Administration (OSHA) highlights that proper waste management systems, including the use of compactors, can decrease the risk of accidents and injuries caused by unmanaged waste. By creating a cleaner and more organized work environment, manufacturers can not only protect their workforce but also foster an atmosphere that encourages efficiency and productivity.

As industries increasingly recognize the importance of sustainability, integrating waste compaction solutions will be essential in achieving both economic and environmental goals.

Comparative Analysis: Different Types of Industrial Waste Compactors

When it comes to managing industrial waste, understanding the comparative analysis of different types of industrial waste compactors is crucial. Various models offer distinct advantages, from vertical compactors that maximize space to horizontal compactors ideal for high-volume operations. Selecting the right type can significantly impact waste management efficiency and operational costs.

Tips for Choosing the Right Compactor: First, assess your waste volume and type. Different compactors are designed for specific materials, so knowing your waste profile is essential. Second, consider the space you have available. Some compactors require more room for operation and maintenance than others. Finally, evaluate the compactor's energy efficiency. Choosing an environmentally friendly option not only benefits the planet but can also reduce long-term operational costs.

Investing in the right industrial waste compactor is a strategic move for any manufacturing operation. A thorough analysis of your options will lead to better waste management practices, ultimately fostering a more sustainable operation.

Best Practices for Maintaining Your Industrial Waste Compactor

Maintaining your industrial waste compactor is essential for ensuring its longevity and efficiency in manufacturing processes. One of the best practices includes conducting regular inspections to check for any signs of wear and tear. Operators should look for issues such as hydraulic leaks, unusual noises, or mechanical malfunctions, which could indicate that the compactor needs servicing. Keeping a detailed maintenance log can help track these inspections, ensuring that all necessary repairs are completed promptly to prevent larger problems down the line.

Additionally, proper training for employees who operate the compactor is crucial. Providing comprehensive training on how to use the machine correctly can significantly reduce the risk of misuse and damage. This includes guidelines on loading materials appropriately and recognizing what types of waste are suitable for compaction. Furthermore, keeping the compactor clean and free from debris can prevent blockages and maintain optimal performance. By adopting these best practices, manufacturers can maximize the efficiency of their waste compactors and contribute to a more sustainable waste management system.

Tips for Selecting the Right Compactor for Your Manufacturing Needs

When selecting the right industrial waste compactor for your manufacturing needs, it's crucial to consider several key factors that align with your specific operations. First, evaluate the type of materials that will be compacted. Different compactors are designed to handle varying waste types, such as cardboard, plastics, or general refuse. Understanding the composition and volume of your waste stream will guide you to a compactor that maximizes efficiency and reduces waste volume effectively.

Next, assess the size and capacity of the compactor in relation to your production output. A unit that is too small may cause frequent collection interruptions, while an overly large compactor could lead to unnecessary costs and space usage. Consider your facility’s layout and the accessibility for maintenance and waste removal, ensuring that the selected unit fits seamlessly into your operational workflow. Furthermore, examine energy efficiency and operational costs, as these factors not only impact your budget but also contribute to a more sustainable manufacturing practice.

Understanding the Standards of Best Industrial Waste Compactors in Manufacturing - Tips for Selecting the Right Compactor for Your Manufacturing Needs

| Feature | Description | Importance | Recommended Specifications |

|---|---|---|---|

| Compaction Ratio | The ability of the compactor to compress waste material. | Higher ratios reduce waste volume and disposal costs. | 4:1 or higher is ideal. |

| Load Capacity | The maximum weight of waste a compactor can handle. | Ensures efficiency and minimizes downtime. | 1,000 - 5,000 lbs depending on the application. |

| Energy Efficiency | Energy consumption during operation. | Reduces operational costs and environmental impact. | Look for models with low kWh per compaction cycle. |

| Safety Features | Built-in mechanisms to protect operators. | Prevents accidents and ensures compliance with health regulations. | Automatic shut-off, safety guards, and emergency stops are essential. |

| Maintenance Requirements | Frequency and type of maintenance needed. | Low maintenance reduces downtime and costs. | Choose models with easy access for service and repair. |