Maximizing Efficiency and Sustainability with Industrial Waste Compactors in Modern Manufacturing

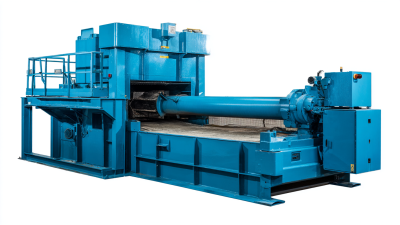

In the modern manufacturing landscape, the emphasis on efficiency and sustainability has never been more critical, as companies strive to minimize costs while adhering to environmental regulations. A pivotal component of this endeavor is the use of Industrial Waste Compactors, which play a crucial role in optimizing waste management processes. According to a report by the Environmental Protection Agency (EPA), effective waste management can reduce disposal costs by up to 50% and significantly lower the carbon footprint associated with waste transport and processing. Furthermore, the Global Waste Management Market is projected to reach $2 trillion by 2027, reflecting the increasing importance of innovative waste solutions, such as compactors, in enhancing operational efficiency. By integrating Industrial Waste Compactors into their operations, manufacturers not only streamline waste handling but also contribute to a circular economy, ultimately promoting sustainable practices that align with corporate social responsibility initiatives.

Enhancing Operational Efficiency through Waste Compaction Techniques

In modern manufacturing, enhancing operational efficiency through waste compaction techniques is crucial for optimizing resources and minimizing environmental impact. Industrial waste compactors play a vital role in this process by significantly reducing the volume of waste generated. By employing advanced compaction methods, manufacturers can streamline their waste management operations, making it easier to transport and process materials. This reduction in waste volume not only cuts down on disposal costs but also speeds up the overall production process, contributing to a more efficient workflow.

Moreover, the integration of smart waste management solutions is revolutionizing this industry. These solutions leverage real-time data analytics and machine learning technologies to provide insights into waste production patterns and optimize collection schedules. By analyzing waste generation in real-time, manufacturers can make informed decisions that lead to reduced waste and improved sustainability. The implementation of these technologies helps in identifying areas for further efficiency gains and ensures that the manufacturing processes align with sustainability goals, resulting in an eco-friendly operation that benefits both the company and the environment.

Maximizing Efficiency and Sustainability with Industrial Waste Compactors in Modern Manufacturing - Enhancing Operational Efficiency through Waste Compaction Techniques

| Waste Type | Monthly Waste Volume (tons) | Compaction Ratio | Operational Efficiency Increase (%) | Estimated Cost Savings ($) |

|---|---|---|---|---|

| Plastic Waste | 50 | 5:1 | 30 | 1,200 |

| Metal Scraps | 40 | 4:1 | 25 | 800 |

| Cardboard | 60 | 6:1 | 35 | 1,500 |

| Wood Waste | 30 | 3:1 | 20 | 600 |

Integrating Smart Technology for Real-Time Waste Management Solutions

The integration of smart technology into waste management systems is transforming modern manufacturing, particularly through the use of IoT solutions. By leveraging real-time data collection and analytics, manufacturers can optimize their waste management strategies effectively. For instance, adaptive collection schedules driven by sensor data can greatly reduce missed pickups, ensuring that waste is efficiently processed. This predictive capability not only enhances operational efficiency but also contributes to sustainability by minimizing the environmental footprint associated with waste disposal.

In addition, the connection of smart bins with AI-powered tracking systems enables seamless waste classification and management. This innovative approach is crucial for creating more resilient urban systems and aligning with the goals of smart city initiatives. By transforming waste into valuable resources, manufacturers can foster a circular economy, where materials are continuously reused and repurposed. The synergistic effect of AI, IoT, and data analytics heralds a new era in waste management, empowering industries to adopt sustainable practices while benefiting from improved resource efficiency and economic gains.

Industrial Waste Management Efficiency

This chart illustrates the reduction of industrial waste generated compared to the implementation of waste compactors in various manufacturing sectors. The data shows the percentage decrease in waste over a year of operation, highlighting the efficiency gained through smart waste management solutions.

Promoting Environmental Sustainability with Advanced Waste Recycling Systems

In today’s manufacturing landscape, the emphasis on environmental sustainability has propelled the adoption of advanced waste recycling systems. These systems significantly contribute to reducing the ecological footprint of industrial operations by maximizing waste recovery and minimizing landfill dependency. By integrating sophisticated recycling technologies, manufacturers can effectively sort, process, and repurpose waste materials, turning what was once considered refuse into valuable resources.

Moreover, industrial waste compactors play a crucial role in promoting these recycling efforts. They not only streamline the waste management process but also enhance efficiency by reducing the volume of waste. This results in fewer pickups and lower transportation costs, further supporting sustainable practices. As manufacturing processes evolve, the synergy between waste compactors and recycling systems exemplifies how companies can embrace sustainability while optimizing their operations, ultimately leading to a cleaner environment and resource conservation.

Cost-Benefit Analysis of Industrial Waste Compactors in Manufacturing

Industrial waste compactors play a critical role in modern manufacturing by significantly enhancing efficiency and sustainability. As manufacturers increasingly adopt compactor monitoring systems, they can optimize the collection frequency of waste, resulting in considerable cost savings. These advanced systems enable companies to track the fullness of compactors, minimizing unnecessary collections and transport, which not only reduces operational expenses but also lowers carbon footprints associated with waste management logistics.

In light of the evolving market dynamics, the demand for industrial waste compactors is projected to rise, reflecting a growing awareness of cost-effective and environmentally friendly waste management solutions. The global trash chute market, for example, is witnessing a shift toward innovative waste handling technologies that streamline processes and contribute to sustainability goals. By investing in these solutions, manufacturers not only enhance their operational efficiency but also align with the increasing regulatory emphasis on sustainable practices in the manufacturing sector.

Best Practices for Implementing Waste Compacting Solutions in Factories

Implementing waste compacting solutions in modern manufacturing is essential for enhancing operational efficiency and promoting sustainability. According to a report by the U.S. Environmental Protection Agency, manufacturing accounts for nearly 20% of the total waste generated in the United States, amounting to around 7.6 billion tons annually. By integrating industrial waste compactors, factories can significantly reduce their waste volume, leading to cost savings in waste disposal and increased recycling rates. Proper waste compaction can reduce waste volume by up to 90%, allowing manufacturers to optimize storage space and transportation logistics.

Implementing waste compacting solutions in modern manufacturing is essential for enhancing operational efficiency and promoting sustainability. According to a report by the U.S. Environmental Protection Agency, manufacturing accounts for nearly 20% of the total waste generated in the United States, amounting to around 7.6 billion tons annually. By integrating industrial waste compactors, factories can significantly reduce their waste volume, leading to cost savings in waste disposal and increased recycling rates. Proper waste compaction can reduce waste volume by up to 90%, allowing manufacturers to optimize storage space and transportation logistics.

Best practices for implementing waste compacting solutions include conducting a thorough waste audit to identify the types and volumes of waste generated. This data can help determine the most suitable type of compactor for specific manufacturing needs. For instance, stationary compactors are ideal for facilities with a consistent flow of waste, while portable compactors offer flexibility for operations with varying waste quantities. Additionally, training employees on the correct usage and maintenance of compactors can improve efficiency. The National Waste & Recycling Association highlights that facilities adopting waste compacting technologies not only enhance their waste management practices but also align with corporate sustainability goals, positively impacting both the environment and the bottom line.

Related Posts

-

Exploring Unique Options for Efficient Waste Management with Vertical Trash Compactors

-

Future Innovations in Compactor Home Technology and How to Leverage Them for Global Procurement

-

2025 Trends in Waste Management: How to Choose the Best Industrial Trash Compactor for Your Business

-

Transforming Waste Management: China’s Premium Garbage Compactors Set New Global Standards

-

The Definitive Guide to Choosing the Best Home Compactor for Your Needs

-

Understanding the Standards of Best Industrial Waste Compactors in Manufacturing