What is an Electric Ball Valve and How Does It Work?

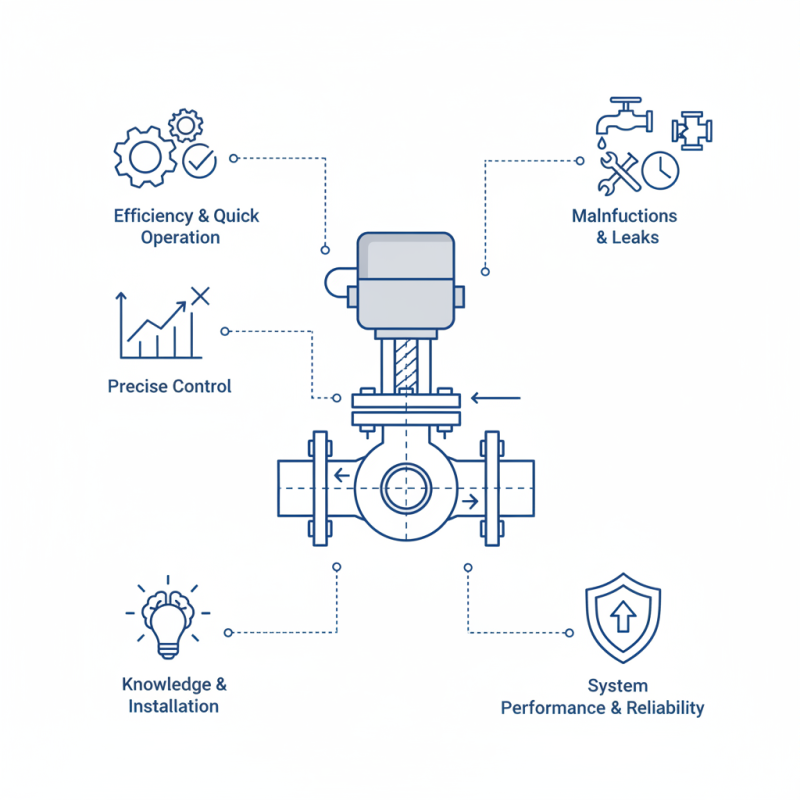

Electric Ball Valves play a crucial role in modern fluid control systems. These devices utilize an electric actuator to operate a spherical disc. This disc controls the flow of liquids and gases through pipes. Users often appreciate their efficiency and quick operation. The design allows for precise control, making them popular in various industries.

However, not all Electric Ball Valves are created equal. Some may malfunction or wear out over time. This can lead to leaks or pressure loss. Regular maintenance is necessary but often overlooked. Users must be aware of their limitations. Knowledge of installation and control is vital to avoid issues.

In conclusion, understanding Electric Ball Valves involves knowing their functions and potential pitfalls. They represent a blend of engineering and practical application. With proper care, they can significantly enhance system performance. Yet, users should remain vigilant about their performance and reliability.

What is an Electric Ball Valve?

An electric ball valve is a type of actuator device. It controls the flow of liquids and gases. Typically, it consists of a ball with a hole that rotates within a pipe. When the ball's hole aligns with the flow, it opens. Turning it 90 degrees stops the flow completely. This simple mechanism provides precise flow control.

One significant feature of electric ball valves is their automation. They are often connected to control systems. This allows for remote operation. In many cases, they respond quickly to commands. Users can create efficient processes in various industries, like water treatment and HVAC.

However, they have some limitations. Power loss can affect operation. If the electricity goes out, the valve may fail to close. Regular maintenance is crucial to avoid malfunctions. This aspect often gets overlooked. In the end, awareness of these issues leads to better usage and reliability.

Key Components of an Electric Ball Valve

Electric ball valves are essential in many industrial applications. They control the flow of liquids and gases. Understanding their key components is crucial to grasp their operation.

Tips: Regular maintenance is crucial. Inspect seals for wear and tear. Ensure the actuator is functioning correctly.

Another important part is the position sensor. This component provides feedback on the valve's position. It helps in automating the control process. Sometimes, the sensors can malfunction, leading to inaccurate readings. Always verify their function.

Tips: Pay attention to wiring. Faulty connections can lead to operational failure. Always consult a professional for complex issues.

How Electric Ball Valves Operate Mechanically

Electric ball valves are essential in many industrial applications. They offer precision control over fluid flow. The design of these valves is straightforward yet effective. A ball with a hole in the center serves as the core component. When the ball rotates, the hole aligns with the pipe for flow. If the ball turns away, it blocks the flow. This simple mechanism makes them reliable.

The operation of electric ball valves involves a motorized actuator. The actuator receives signals from a control system. It then turns the valve's ball to the desired position. Most often, these valves work using a 90-degree turn. This allows for quick shut-off or full flow. The electrical aspect provides smooth operation. However, if there is an electrical failure, the valve can become inoperable.

In practice, maintenance is crucial. Regular inspections help ensure that the actuator, seals, and ball function correctly. Accumulated debris can hinder movement, causing leaks or blockages. Electric ball valves require careful calibration. An incorrect setting can lead to inefficient system performance. Understanding these aspects is vital for optimal use.

Advantages of Using Electric Ball Valves

Electric ball valves offer distinct advantages. These valves provide quick and accurate flow control. They operate through an electric motor that rotates a ball with a hole. This design ensures efficient shut-off capabilities. A report by Markets and Markets states that the electric valve market is projected to reach $9.6 billion by 2025, indicating rapid growth.

One benefit is energy efficiency. Electric ball valves minimize energy loss. They often require less maintenance than manual valves. However, installation costs can be high. Another advantage is automation integration. These valves can easily connect to digital management systems. Yet, reliability can sometimes be an issue due to electronic components.

These valves also offer precision. They can regulate flow to within ±1% accuracy. According to a study by the Valve Manufacturers Association, up to 40% of process-related issues trace back to valve performance. In industries like water treatment and oil & gas, this accuracy is vital. But, improper sizing or selection may lead to inefficiencies. Choosing the right valve requires careful consideration of the specific application.

Advantages of Electric Ball Valves

Common Applications of Electric Ball Valves

Electric ball valves are widely used in various industries. Their ability to control the flow of liquids and gases makes them invaluable. These valves are efficient and reliable in environments such as water treatment facilities, HVAC systems, and chemical plants. According to a recent industry report, the global electric valve market is projected to reach $5.4 billion by 2026, highlighting their increasing importance.

In HVAC applications, electric ball valves help regulate temperature and airflow. They can easily control heating and cooling systems. The accuracy they provide minimizes energy waste. In the food and beverage industry, these valves ensure hygiene and support automation. Their robust design withstands harsh conditions, but they can sometimes struggle with debris in fluids. Regular maintenance is necessary to ensure optimal performance.

Energy efficiency drives the use of electric ball valves in irrigation systems. They allow farmers to control water usage effectively. This precision supports sustainable agriculture. Electric ball valves can simplify installation, but improper fitting can lead to leaks. Balancing cost and quality remains a challenge for many users. Despite these hurdles, their benefits cannot be overlooked.