Why Are Die Casting Molds Essential for Manufacturing Success?

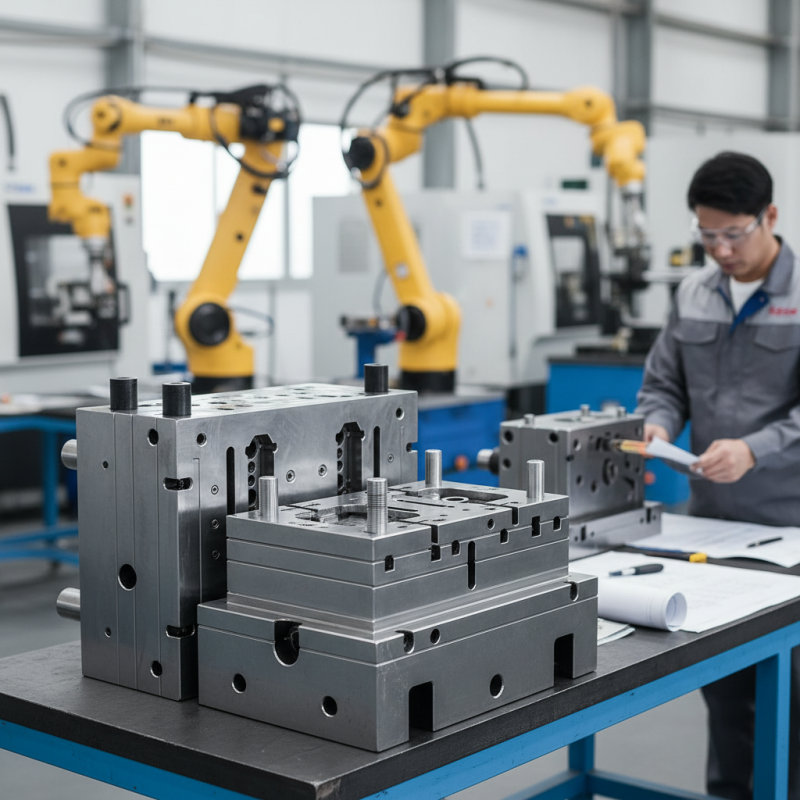

Die Casting Molds play a vital role in the manufacturing sector. These molds ensure precision and efficiency, crucial for producing high-quality components. According to a recent report by MarketsandMarkets, the die casting market is projected to reach $55.78 billion by 2026. This growth underscores the importance of effective mold design and usage.

Industry expert John Smith, a renowned figure in die casting technology, says, "The quality of a product starts with the mold." His insights remind us that not all molds are created equal. Many manufacturers overlook mold maintenance and design. This can lead to production delays and increased costs. Failing to invest in quality Die Casting Molds can undermine overall productivity.

In conclusion, Die Casting Molds are not just tools; they are essential to achieving manufacturing success. Proper attention to design and upkeep can make a significant difference. However, the challenge remains: how can companies balance cost with quality? This is an ongoing discussion in the industry.

Importance of Die Casting Molds in the Manufacturing Process

Die casting molds play a vital role in the manufacturing process. They ensure precision and consistency in every product. A well-designed mold can reduce waste and improve efficiency. According to recent industry reports, companies using optimized die casting molds can increase production speed by up to 30%. This improvement significantly impacts overall manufacturing success.

Tips: Maintaining molds is crucial. Regular inspections can prevent costly breakdowns. Clean molds after each use to avoid impurities. Take time to analyze production data post-mold usage. This reflection can reveal patterns that need attention, such as areas for improvement. A proactive approach can lead to long-term success and better product quality.

Key Materials Used in Die Casting Molds and Their Properties

Die casting molds play a vital role in the manufacturing process. They are crafted from various materials, each with distinct qualities. Aluminum is a common choice, noted for its lightweight and excellent thermal conductivity. This allows for efficient heat transfer during the casting process. However, aluminum molds can wear out over time, needing replacements.

Another material often used is steel. Steel molds are durable and can withstand high pressures. They provide a longer lifespan compared to aluminum molds. Yet, their higher cost can lead to budget constraints for smaller manufacturers.

Copper is also a notable material. It excels in thermal conductivity and can enhance production efficiency. The downside? Copper molds can be expensive and require careful handling. Manufacturers must weigh these options thoughtfully. Choosing the right material impacts the overall success of die casting projects, influencing both quality and cost-effectiveness.

Key Materials Used in Die Casting Molds and Their Properties

| Material | Properties | Applications |

|---|---|---|

| Aluminum Alloy | Lightweight, good thermal conductivity, high corrosion resistance | Automotive parts, consumer electronics |

| Zinc Alloy | High strength, excellent surface finish, die-castable | Hardware, furniture components |

| Magnesium Alloy | Very lightweight, high strength-to-weight ratio, good machinability | Aerospace components, automotive parts |

| Copper Alloy | Excellent electrical conductivity, high thermal conductivity, resistant to corrosion | Electrical connectors, heat exchangers |

| Steel | High strength, durability, suitable for high-volume production | Durable tooling, industrial parts |

Impact of Die Casting Molds on Production Efficiency and Cost Reduction

Die casting molds play a crucial role in enhancing production efficiency. According to the American Foundry Society, manufacturers can reduce production time by up to 30% when using high-quality die casting molds. These molds are designed for precision, ensuring parts are produced consistently. The right mold reduces waste. Lower material waste translates to significant cost savings, a fact supported by a recent report from the Metal Industries Association, suggesting that manufacturers can slash costs by nearly 20% with better mold design.

Durability is another key factor. High-quality molds last longer, decreasing the need for frequent replacements. An industry study revealed that durable molds can last up to four times longer than their lower-quality counterparts. However, achieving this durability requires investment upfront. Some companies hesitate to spend on premium molds, risking inefficiency and increased long-term costs.

Moreover, producing complex shapes becomes easier with advanced molds. This flexibility in design enhances the range of products offered. Yet, the complexity of mold design can lead to challenges. Inexperienced manufacturers may struggle with these intricate designs, impacting production timelines. Overall, while the benefits of die casting molds are substantial, the initial hurdles and costs must be carefully navigated for successful implementation.

Trends in Die Casting Mold Technology: Innovations and Future Prospects

Die casting mold technology is evolving rapidly. Innovations are critical for maintaining competitiveness in the manufacturing sector. Reports indicate the die casting market is expected to reach USD 11.7 billion by 2027, growing at a CAGR of 5.6%. This growth is largely driven by advancements in mold materials and design processes. New composite materials enhance durability and performance.

3D printing technology is becoming a game-changer in mold design. It allows for rapid prototyping and complex geometries that were previously unachievable. This also significantly reduces lead times. Manufacturers are increasingly adopting these advanced technologies to optimize production workflows. However, there are challenges. Integrating new solutions requires investment and worker training. Companies must adapt to this pace of change or risk falling behind.

Tip: Regularly evaluate your mold technologies. Stay updated on emerging trends. This can prevent costly setbacks down the line. Consider partnerships with tech providers for better insights.

As more manufacturers go green, sustainable practices are taking center stage. Using recyclable materials in die casting molds can reduce waste significantly. Yet, not all companies are ready to make that leap. Balancing cost with sustainability remains a key issue. Some firms may be hesitant due to initial investment concerns. Understanding the long-term benefits is essential.

Quality Control Measures in Die Casting Mold Production and Maintenance

Die casting molds play a critical role in the overall quality of production. Ensuring their reliability is essential for achieving excellent results. Regular inspection of molds can prevent potential defects. This process involves checking for wear, damage, and accuracy. Quality control starts here. However, it is often overlooked. Skipping these checks can lead to costly mistakes.

Proper maintenance is equally important. Regular cleaning is necessary to remove residue that can affect the final product. Operators must be trained to carry out these tasks effectively. Yet, many workers lack proper training. This gap can lead to inconsistencies in mold performance. For instance, a mold may appear operational but can produce subpar parts without adequate maintenance.

Moreover, documentation of the maintenance activities is a crucial aspect of quality control. Records help track the condition of molds over time. Unfortunately, not all manufacturers prioritize comprehensive documentation. This can create confusion and inefficiencies in the production process. Implementing rigorous quality control measures, therefore, remains a must for manufacturers aiming for success in die casting.