How to Choose the Best Metallurgical Bridge Crane for Your Needs?

Choosing the right Metallurgical Bridge Crane is crucial for your operations. This decision impacts productivity and safety. With various options available, it can be overwhelming. Each crane differs in performance, capacity, and features.

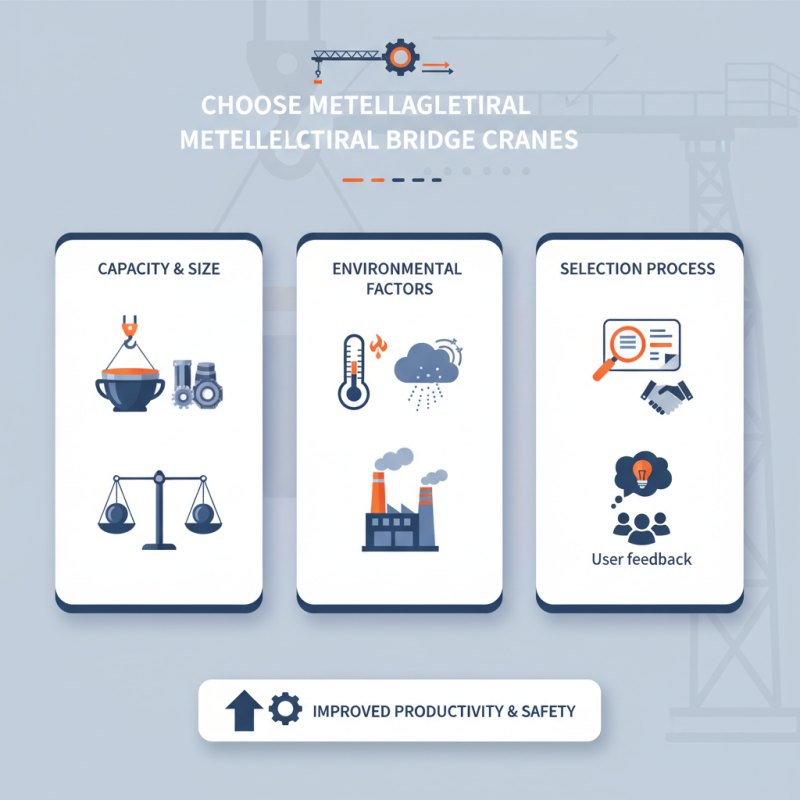

Consider the specific needs of your facility. Are you lifting heavy metals or handling smaller components? The size and weight capacity of the Metallurgical Bridge Crane will play a vital role. If you overlook these factors, it may lead to inefficiencies. Additionally, evaluate the environment where it will be used. Extreme temperatures or dust can affect crane performance.

Don’t rush the selection process. Take time to assess your needs carefully. Engaging with manufacturers can help clarify uncertainties. Seek feedback from existing users to understand their experiences. Reflecting on these aspects can guide you to make a more informed decision. Ultimately, the right choice can enhance your operations significantly.

Understanding the Basics of Metallurgical Bridge Cranes

Metallurgical bridge cranes play a vital role in processing and transporting heavy materials. Understanding their design and features is essential for your operations. These cranes typically span large areas, offering flexibility in moving materials efficiently. They can lift substantial weights, which is crucial in metalworking environments.

When considering a metallurgical bridge crane, focus on your specific needs. Assess the weight capacity required for your materials. Ensure the crane can accommodate the dimensions and type of goods you handle. Different crane systems feature various lift heights and spans. It’s necessary to reflect on the space constraints in your facility.

Evaluate materials and construction of the crane. Material durability impacts safety and longevity. A well-constructed crane may require more investment but offers fewer maintenance issues. Yet, it's vital to analyze your budget and make trade-offs. No choice is perfect; each decision involves careful consideration of costs versus benefits.

Identifying Your Specific Lifting Requirements and Applications

Choosing the right metallurgical bridge crane starts with identifying your specific lifting requirements. Various industries have unique needs. For example, steel production facilities often require cranes capable of lifting heavy slabs weighing over 100 tons. In such cases, a crane's load capacity and height restriction become critical. According to an industry report, nearly 40% of crane failures stem from exceeding their load limits. This highlights the importance of matching specifications to your operational needs.

The type of materials handled also affects your choice. For instance, if you're lifting molten metal, consider heat resistance features. Reports indicate that improper handling in such environments could lead to significant safety hazards, with incidents costing companies millions in downtime. Additionally, lifting speed and precision are essential for tasks requiring efficiency. Some applications demand high-speed operations, while others focus on precision over speed. Thus, understanding these nuances helps in selecting a crane design that minimizes risk.

Other factors include the crane's operational environment. Cranes operating outdoors face weather challenges like wind or rain. Indoor setups may require more compact designs to navigate limited spaces. A comprehensive assessment of your working environment and load requirements leads to a better choice. Gathering input from your operational team can further illuminate these specific challenges.

Evaluating Key Features and Specifications of Bridge Cranes

When selecting a metallurgical bridge crane, it’s crucial to evaluate specific features and specifications. Load capacity is one of the first factors to consider. Cranes can typically handle loads ranging from 1 ton to over 100 tons. According to a recent study, nearly 70% of crane failures are due to overloading. Thus, choosing the right load capacity is vital for safe operation.

Another important specification is the span length. Span lengths vary from 20 feet to over 100 feet, depending on the application. A wider span can increase efficiency but may require more structural support. Proper assessment can help avoid costly modifications later. Additionally, speed plays a role. Cranes often operate between 10 to 100 feet per minute. High-speed operations may lead to increased wear if not properly managed.

Safety features must not be neglected. Many cranes are equipped with overload sensors and emergency stop features. Industry reports suggest that effective safety systems can reduce accidents by up to 40%. However, not all cranes come standard with these features. Carefully researching safety options can prevent potential issues. Always weigh these specifics against your operational demands to ensure the best choice for your needs.

Key Features of Metallurgical Bridge Cranes

Comparing Different Brands and Models for Quality and Performance

Choosing the right metallurgical bridge crane involves comparing various brands and models. Each option has unique features. Some cranes excel in lifting capacity, while others focus on speed and efficiency. Analyze how these factors influence your specific needs.

Durability is another critical aspect. Some models perform better in harsh environments. They resist high temperatures and heavy loads. However, they may come at a higher price. It's essential to weigh performance against budget constraints. A less expensive model might save money but could lead to higher maintenance costs later.

Don't neglect customer reviews. They offer real-world insights. Understand common issues users face. Some cranes may have outstanding specs on paper but fail in practice. Look for feedback on reliability and service after the sale. Balancing these considerations will help you make a more informed decision.

Considering Budget, Maintenance, and After-Sales Support Options

When selecting a metallurgical bridge crane, it's essential to focus on budget, maintenance, and after-sales support. The initial cost is crucial. Reports suggest that around 30% of companies underestimate long-term expenses. A crane may seem affordable upfront, but hidden costs can rise quickly. Regular maintenance is often overlooked, leading to unplanned downtime.

Maintenance frequency varies by model, but some require checks every 1 to 3 months. Ignoring routine upkeep can decrease operational efficiency by 20%, according to industry studies. It's vital to understand the specifics of the maintenance contract before committing. This contract can reveal potential long-term financial impacts.

After-sales support is another critical area. A 2022 industry survey indicated that 65% of organizations faced issues due to inadequate support. Quick responses matter. It’s worth asking about response times for technical queries. Technical support available 24/7 can save considerable stress and loss. Be cautious; support quality can differ significantly across suppliers. Knowing this can save you headaches down the road.

How to Choose the Best Metallurgical Bridge Crane for Your Needs?

| Criteria | Budget Range (USD) | Maintenance Frequency | After-Sales Support |

|---|---|---|---|

| Heavy Duty Bridge Crane | 50,000 - 100,000 | Quarterly | 24/7 Support |

| Standard Bridge Crane | 30,000 - 60,000 | Bi-Annual | Business Hours Support |

| Lightweight Bridge Crane | 10,000 - 25,000 | Annual | Limited Support |

| Custom Engineered Crane | 100,000+ | As Needed | Dedicated Support |