How to Choose the Right Plastic Injection Mold for Your Project?

Choosing the right Plastic Injection Mold for your project can feel overwhelming. Many factors are at play. A well-selected mold can streamline production and ensure quality. However, making a poor choice can lead to delays and extra costs.

Consider the specifics of your project. What material will you use? How complex is the design? These questions are crucial. It's easy to overlook details. For instance, weight distribution in your mold can affect the final product's strength.

Don't just focus on the price. The cheapest option may not always deliver the best results. Reflect on the long-term benefits of a quality mold versus short-term savings. Finding the perfect Plastic Injection Mold requires careful thought. Each decision can significantly impact your project's success.

Understanding the Basics of Plastic Injection Molding

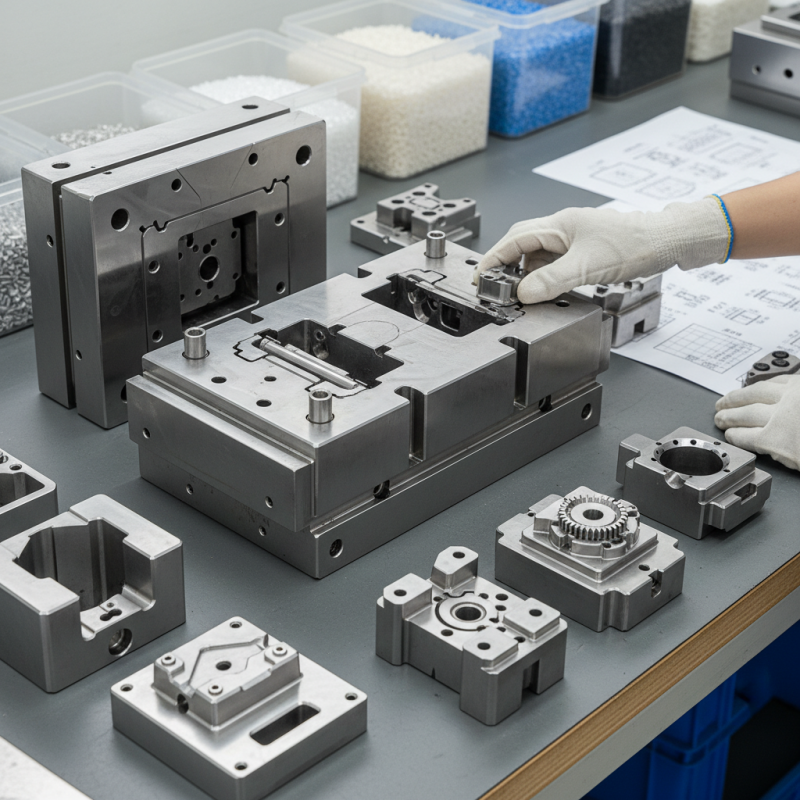

Plastic injection molding is a widely used method for creating durable plastic products. It involves injecting molten plastic into a mold, allowing it to cool and harden into the desired shape. Understanding the basics can improve your project outcomes. The right mold can enhance efficiency and reduce waste.

Molds come in various designs and materials. While steel molds are durable, they can be expensive. Aluminum molds, on the other hand, offer a quicker turnaround time but may wear out faster. It’s crucial to assess your project’s needs. Consider production volume and budget limitations. Each choice has pros and cons that could impact the final product.

The cooling process requires careful attention. Inadequate cooling may result in warping. Ensure the mold’s design allows for proper heat dissipation. If not, you might face delays and increased costs. Reflect on past experiences and adjust your approach. Learning from mistakes can lead to better decisions in future projects.

Identifying Your Project Requirements for Mold Selection

When selecting the right plastic injection mold, the primary step is understanding your project requirements. This may seem straightforward, but it often requires deeper analysis. According to industry reports, nearly 70% of molding issues stem from inadequate requirements definition. A clear understanding helps prevent costly mistakes in the future.

Identify the material you will use. Different plastics have distinct properties. Choosing the wrong material can lead to product failure. For instance, using a low-grade plastic for high-stress applications may cause premature wear. Additionally, consider the complexity of your design. A complex mold might not be feasible or could drastically increase costs. Data suggests that production costs can climb by up to 30% with intricate designs.

Evaluate the production volume as well. High-volume projects benefit from optimized molds, while small productions may require flexible solutions. Each mold type varies greatly in cost and durability. If you overlook this aspect, you might face delays or additional expenses. A clear, reflective approach to your mold selection process will yield better results and potentially improve your product lifespan.

Evaluating Material Options for Injection Molding

When selecting materials for injection molding, several factors come into play. The specific requirements of your project will greatly influence your choice. Consider the physical properties needed, such as strength, flexibility, or chemical resistance.

Common materials include thermoplastics like ABS and polycarbonate. These offer various levels of durability and heat resistance. However, they may not always be the best fit for every application. Evaluate how the material reacts to stress and environmental conditions. Sometimes, a material that looks great on the surface might not perform well in real-world situations.

The cost of the materials cannot be overlooked. Some options are much more affordable, while others can significantly increase project expenses. It's wise to balance cost and performance. Many professionals overlook the long-term implications of choosing cheaper materials. They might save money initially but face higher costs down the line due to product failures.

Take your time in assessing your options; this ensures a better outcome for your project.

Assessing Design Complexity and Mold Features

When choosing a plastic injection mold, assessing design complexity is crucial. Complex designs may require multi-cavity molds or specialized features. These molds can handle intricate parts with tight tolerances. However, such molds may come with a higher cost. The complexity can also lead to longer lead times and potential challenges in manufacturing.

Mold features play a significant role in functionality. For example, cooling channels are essential for heat transfer. A well-designed channel can improve cycle times. Similarly, consider the ejection system. Some designs require additional components for part removal. These features can influence your production efficiency. Balancing complexity and features is key. Reflect on your project's priorities. Are you focused on speed or precision? Understanding this helps in making informed choices.

How to Choose the Right Plastic Injection Mold for Your Project? - Assessing Design Complexity and Mold Features

| Feature | Description | Complexity Level | Recommended Material |

|---|---|---|---|

| Core/Cavity Design | Shape and structure of the mold’s core and cavity | High | Steel |

| Gate Design | Entry point for molten plastic | Medium | Aluminum |

| Ventilation | Allows air to escape during filling | Low | N/A |

| Cooling System | Regulates the temperature during the injection process | Medium | Copper |

| Ejection System | Mechanism for ejecting the finished part | High | Steel |

Considering Cost and Time Factors in Mold Acquisition

When selecting a plastic injection mold, cost and time are critical factors. Budget constraints often steer decisions. A low-cost option may seem appealing, but it can lead to unforeseen expenses later. Quality is paramount. Cheaper molds can break down easily, resulting in additional production delays. Evaluating the initial investment against potential long-term costs is essential.

Time is another crucial consideration. Short lead times can be tempting. However, rushing the process might compromise quality. It's vital to ensure that your chosen manufacturer has a solid timeline. Communication during the production phase keeps you informed. A delay in delivery could disrupt your entire project plan.

Lastly, don’t overlook the importance of prototyping. Creating a prototype might extend your timeline but can unveil design flaws early. It might add initial costs, but it saves money later on. Reflecting on your priorities is key. Balancing cost and time requires careful thought and planning. Make decisions that align with your project goals, not just immediate savings.