How to Choose a Damper Actuator for Your HVAC System?

In today's HVAC industry, selecting the right Damper Actuator is crucial. A well-chosen actuator improves system efficiency and comfort. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper actuator selection can lead to energy losses up to 30%.

Dr. Emily Sanders, a renowned expert in HVAC automation, emphasizes, “Choosing the right Damper Actuator can transform system performance.” This insight highlights the importance of understanding the specific needs of your HVAC system. A poorly selected actuator may underperform, increasing operational costs and reducing comfort levels.

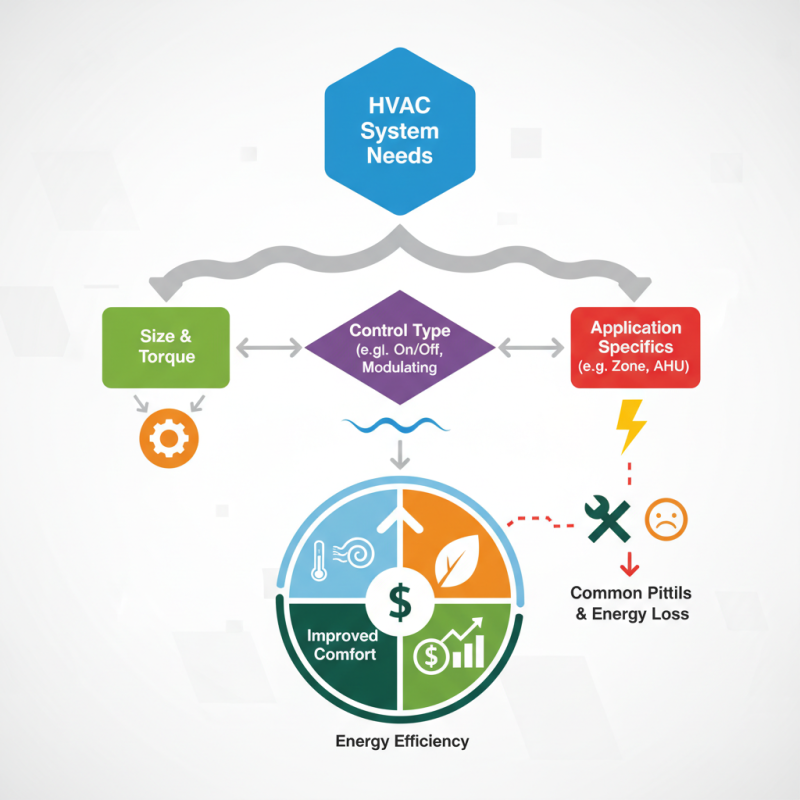

Selecting a Damper Actuator requires careful consideration of factors like size, torque, and control type. Each application is unique. The decision-making process can be daunting, often leading to mistakes. Balancing performance and cost constraints can feel overwhelming. Ensuring the actuator meets requirements is essential for optimal performance and energy efficiency.

Understanding the Role of Damper Actuators in HVAC Systems

In HVAC systems, damper actuators play a crucial role in controlling airflow. They regulate the position of dampers, allowing for precise airflow management. This regulation helps maintain indoor air quality and temperature. Proper functioning of these actuators is vital for system efficiency.

When selecting a damper actuator, consider its compatibility with your HVAC system. Not all actuators fit every system type. Look into the actuator’s torque and speed specifications. These details determine how quickly and effectively it can respond to changes. Improper specifications may lead to inadequate airflow control.

A common mistake is neglecting the actuator’s power requirements. Ensure it matches your current setup to avoid system failures. Regular maintenance checks are key. Failing to inspect these components can lead to problems down the line. Awareness of potential issues helps in making better choices and maintaining a reliable HVAC system.

Types of Damper Actuators: A Comprehensive Overview

When evaluating damper actuators for HVAC systems, it’s essential to understand the types available. Two primary categories are electric and pneumatic actuators. Electric actuators are popular due to their precise control and ease of integration with modern systems. These actuators often feature stepper motors, which allow for accurate positioning. According to industry reports, electric actuators constitute nearly 55% of the market in HVAC applications.

Pneumatic actuators, on the other hand, rely on air pressure to function. They are favored in environments where electrical components may pose a safety hazard. However, their responsiveness can be slower compared to electric actuators. In some instances, this delay can impact system efficiency. Data indicates that pneumatic actuators account for about 30% of the overall market, emphasizing their importance in specific applications.

Damper actuators also vary in size and torque capabilities. Selecting an actuator with inadequate torque can lead to operational failures. It's crucial to analyze the specific requirements of each HVAC system. Overlooking this aspect often leads to suboptimal system performance. Many systems can benefit from a dual approach, combining both actuator types for enhanced efficiency and reliability. Careful consideration of these types allows for better energy management and environmental control within buildings.

How to Choose a Damper Actuator for Your HVAC System?

| Type of Damper Actuator | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Electric Actuators | Use electrical power to control damper position. | Commercial buildings, HVAC systems. | Precise control, quick response time. | Dependence on electricity, higher installation cost. |

| Pneumatic Actuators | Utilize compressed air for operation. | Industrial applications, air handling units. | Robust, reliable in harsh conditions. | Requires air supply, slower than electric actuators. |

| Hydraulic Actuators | Use hydraulic fluid to create motion. | Heavy industry, large HVAC systems. | High force output, durable. | Complex system, potential leakage issues. |

| Spring-Return Actuators | Use a spring mechanism to return to a default position. | Safety applications, emergency systems. | Fail-safe operation, reliable. | Limited control over positioning. |

Key Factors to Consider When Selecting a Damper Actuator

Choosing the right damper actuator for an HVAC system involves several critical factors. The actuator type matters. You can opt for electric or pneumatic options. Electric actuators are easier to implement. Pneumatic actuators, however, can handle larger loads. Consider the required torque as well. The actuator must match the damper size and pressure.

Another essential factor is the control method. Some actuators are simple on/off models. Others offer modulating control, allowing for more precise adjustments. Think about the system's complexity when deciding. Integration with existing controls matters too. Ensure compatibility with your HVAC's control system. Sometimes, communication can fail due to mismatched protocols.

Don't overlook environmental conditions. Extreme temperatures can affect performance. Humidity levels also play a role in actuator reliability. Make sure to check the specifications.

Improper selection can lead to inefficient operation. This might worsen the overall system performance. Reflect on your choices carefully to avoid costly mistakes down the line.

Evaluating the Compatibility of Actuators with HVAC Components

Choosing the right damper actuator for your HVAC system involves several factors. The compatibility of the actuator with existing system components is a key consideration. Different actuators operate on various principles, such as electronic or pneumatic. Each type interacts uniquely with ductwork, valves, and controllers. It's crucial to assess these elements closely.

Incorrect compatibility can lead to inefficiency. For instance, an actuator that lacks sufficient torque might struggle to open or close dampers effectively. This could result in uneven airflow or increased energy consumption. Additionally, factors such as size and mounting flexibility are often overlooked. They can cause installation headaches.

Pay attention to control signals too. Some actuators require specific voltage ranges. Verify that your HVAC system can accommodate these specifications. This diligence can prevent future operational issues. Testing different options may be necessary to find the optimum fit. A thoughtful choice will enhance HVAC performance, but don’t hesitate to seek expert advice if needed.

Damper Actuator Compatibility in HVAC Systems

This bar chart illustrates the compatibility ratings of different types of damper actuators commonly used in HVAC systems, helping to evaluate which actuator type is best suited for specific HVAC components.

Best Practices for Installation and Maintenance of Damper Actuators

Installing and maintaining damper actuators is crucial for efficient HVAC performance. First, make sure the actuator is compatible with your system. Check the voltage, torque, and control signals. Improper selection can lead to malfunctions or inadequate airflow control. Simplicity is key; avoid overly complex setups that complicate troubleshooting.

When installing, ensure that the actuator is mounted securely. Misalignment can cause wear and tear. Use a level to keep it straight. Additionally, observe the actuator during operation. Look for unusual noises or erratic movement. These signals often indicate a need for maintenance. Don’t ignore minor issues as they could lead to bigger problems later.

Perform routine checks to ensure fluid movement and clean components regularly. Dust and debris can hinder performance significantly. Use a soft cloth to wipe down the actuator. Keep connections tight but do not overtighten, as that can create new problems. Document any maintenance work. This record can help identify patterns in failures or performance issues. Regular reflection on these practices is essential for long-term efficiency.