What is an Alloy Powder Grader and How Does it Work?

In the realm of materials science, the "Alloy Powder Grader" stands as a critical tool. It plays a vital role in ensuring the quality and consistency of alloy powders used in various applications. Dr. Emily Carter, a leading expert in powder metallurgy, emphasizes, "The precision of an Alloy Powder Grader can significantly influence the performance of the final product."

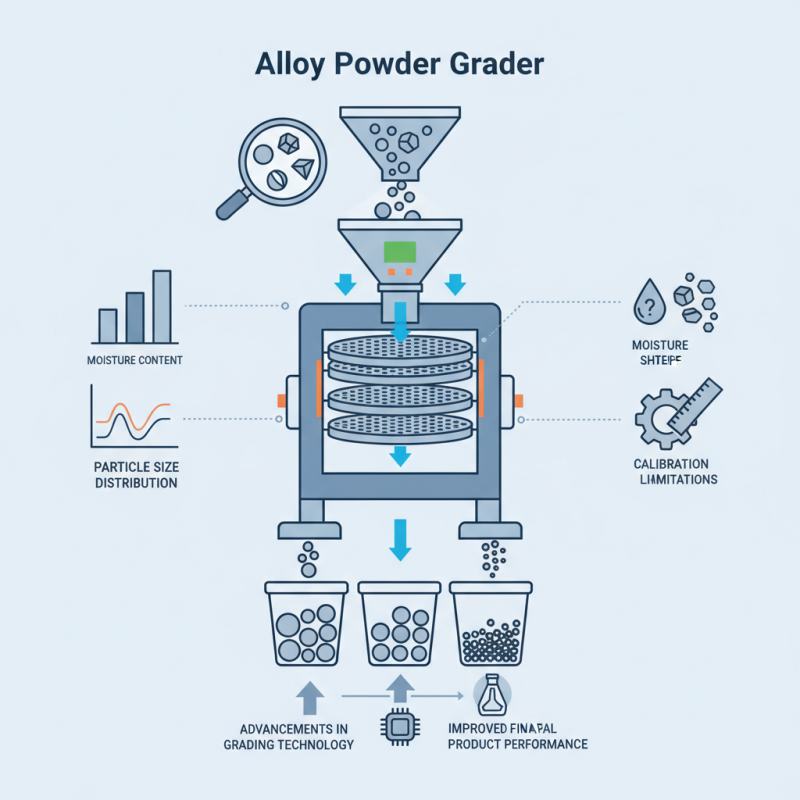

Alloy Powder Graders operate by assessing the particle size distribution of powders. This process ensures that manufacturers can achieve the desired properties in their materials. However, the technology is not without its limitations. The accuracy of measurements can be affected by factors such as powder shape and moisture content.

Despite the advancements in grading technology, discrepancies still exist. Companies frequently face challenges in calibrating their equipment. Understanding these nuances is crucial for optimizing production. As the industry evolves, the need for precise grading systems becomes increasingly evident, pushing for improvements in Alloy Powder Graders.

What is an Alloy Powder Grader?

An alloy powder grader is an essential tool in material science. It plays a vital role in analyzing and classifying metal powders. Accurate grading affects the final product's quality and properties. In industries like aerospace and automotive manufacturing, this precision becomes crucial. Reports show that over 60% of manufacturers rely on high-grade metal powders to enhance their production.

The grading process involves several steps. Initially, the alloy powders are fed into the grading system. Sensors and screens separate particles based on size and density. This process is not always perfect. Sometimes, fine powders can escape detection. In fact, studies indicate that about 15% of materials may be misclassified. This error can lead to defects in the final products.

Quality control is paramount. Real-time monitoring ensures that the powders meet industry standards. However, the technology is not foolproof. Variability in the raw materials can produce inconsistent results. As a result, manufacturers need to regularly calibrate their equipment. Industry data highlights that consistent calibration can improve accuracy by up to 25%. Continuous improvement in alloy powder grading remains a focus for many companies.

Key Components of Alloy Powder Grading Machines

Alloy powder grading machines are crucial in the manufacturing sector. They ensure consistent quality and performance of powder products. These machines rely on several key components to efficiently classify and grade alloy powders.

The grading chamber is another vital component. It separates powders based on particle size. Commonly, this chamber uses a series of sieves. The sieves help in categorizing the powder for specific applications. Insights from reports indicate that a well-optimized grading chamber can improve efficiency by up to 30%. However, some chambers may need adjustments over time. Regular maintenance is necessary to avoid wear and ensure precision.

Tips: Regularly inspect the vibratory feeder for wear. Small cracks can disrupt flow. Proper calibration ensures accurate grading. Consider your powder's properties when selecting sieves. Each type affects the final product quality.

How Alloy Powder Graders Function: A Step-by-Step Process

Alloy powder graders play a crucial role in metal processing. They ensure consistency in particle size and distribution. This is essential for many industries. The grading process typically involves a series of mechanical and electromechanical actions.

In operation, raw alloy powder is fed into the grader. Vibrations help break clumps. This creates a uniform flow through sieves of varying mesh sizes. The finer particles pass through, while larger ones are retained. The graded powders can be collected separately. Each fraction can be analyzed for quality and properties.

However, issues may arise during this process. Some fluctuating factors like humidity can affect grading. Operators must monitor conditions closely. Sometimes the resulting powder may not meet specifications. This requires adjustments or a reevaluation of methods. Even with technology, the grading process demands human oversight to maintain quality.

What is an Alloy Powder Grader and How Does it Work?

| Parameter | Description | Importance |

|---|---|---|

| Particle Size | Measurement of the diameter of particles in the powder. | Critical for determining the flowability and sintering properties. |

| Density | Mass per unit volume of the powder. | Influences the packing and mechanical properties of the final product. |

| Composition | The specific metal and element ratios present in the alloy powder. | Affects the performance characteristics and applications of the alloy. |

| Flow Rate | Speed at which the powder flows through a given opening. | Determines the efficiency of processing and handling of the powder. |

| Moisture Content | Amount of moisture present in the alloy powder. | Impacts the quality and stability of the powder during storage and processing. |

Applications of Alloy Powder Grading in Various Industries

Alloy powder grading plays a crucial role across various industries. In manufacturing, precise alloy powders improve product quality. These powders are used in 3D printing, providing strength and durability to printed components. They are essential in aerospace and automotive sectors, where lightweight materials are critical.

Pharmaceutical industries also benefit from alloy powder grading. Accurate grades help in creating more effective delivery systems. This enhances medication efficacy and patient outcomes. Construction materials, such as high-strength concrete, rely on specific alloy powders. These contribute to building resilient structures.

Tip: Regular checks on the grading process can prevent costly errors in production. Ensure that your grading equipment is well-maintained to achieve optimal results.

Another consideration is environmental impact. The process of alloy powder production can generate waste. It's important to assess recycling options for any unused material. Being mindful of waste can enhance sustainability efforts.

Tip: Always seek feedback from quality control teams. Their insights can help refine the grading process and improve overall efficiency.

Advantages of Using Alloy Powder Graders in Production

Alloy powder graders play a vital role in production. They ensure consistent particle size distribution. This consistency is crucial for quality control. When the particle sizes vary, it can affect the final product. For instance, inconsistencies might lead to uneven melting or binding in processes like 3D printing.

Using alloy powder graders offers several advantages. They help in optimizing the manufacturing process. With precise grading, production efficiency increases. This can reduce waste and save time. Operators can achieve better accuracy in material properties. Additionally, when powders are uniformly distributed, equipment wear and tear may decrease, extending the lifespan of machinery.

Despite these advantages, challenges exist. The initial setup of grading equipment can be complex. Regular maintenance is necessary to keep machines running smoothly. Moreover, not all materials behave the same. Some alloys may require specific grading approaches. This calls for ongoing learning and adjustment in operations. Users may need to reflect on their methods regularly to achieve the best outcomes.